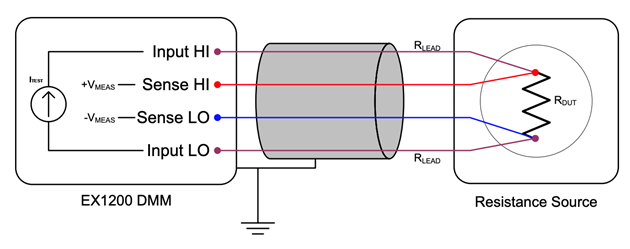

Improve Accuracy and Reliability When Making Four-Wire Resistance Measurements

When accuracy really counts, you should make four-wire resistance measurements. Sometimes referred to as the Kelvin method, the four-wire resistance method is often used in automated test applications where long cable lengths, numerous connections, or switches exist between the digital multimeter (DMM) and the device under test (DUT).

Read More